![]()

Jet

Engine (Little Advanced) || ATMOSPHERIC

JET ENGINES || Important Links

Jet Engine Basics for the Beginner

The object of a commercial

airliner's turbofan engines is to provide thrust for the aircraft. The positive

force of thrust balances or exceeds the force of drag. Thrust gives the forward

motion needed to sustain lift. This thrust can be used to accelerate, climb,

maneuver, or simply to overcome the aircraft's drag and cruise.

How does a jet engine make thrust?![[Jet Engines]](images/aviati1.gif)

Isaac Newton once said, "Actio est reacto." For those of us who

never learned Latin, that means: "for every action there is an equal

and opposite reaction." If you shoot air out the nozzle of an

airplane fast enough (the action), your airplane will be propelled

forward (the reaction). You can make your own jet thrust action

using a balloon. Blow it up, but don't tie the end. Let it go. What

happens? Air trapped inside the balloon pushes out the open hole, causing

the balloon to travel forward... just like a jet engine. But jet airplanes

don't carry giant balloons around with them! There's no easy way to blow

them up while you're flying around!

The Jet Principle![[Balloon]](images/aviati2.gif)

Here's that balloon again. Even though it does make a jet, a balloon isn't

practical for jet airplanes because, among other things, you'd have to

blow it up and keep it blown up the whole time you're flying. We need

something else to "blow up" the air ahead of an airplane and

make it jet out the back so that it can provide useful thrust. Aircraft

designers use jet engines. There are many types, but they all follow the

same "action" and "reaction" laws as the balloon.

Here's how they work.

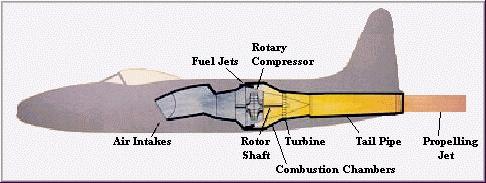

Jet Engine Design

![[Engine Layout]](images/aviati3.gif) Here's the layout of a typical air-breathing jet engine. There are a lot

of variations, but they all have some way to suck in the air (the inlet),

squeeze the air (the compressor), add heat to the air (the combustor),

provide work for the squeezing process (the turbine), and blow the

air out the back (the nozzle).

Here's the layout of a typical air-breathing jet engine. There are a lot

of variations, but they all have some way to suck in the air (the inlet),

squeeze the air (the compressor), add heat to the air (the combustor),

provide work for the squeezing process (the turbine), and blow the

air out the back (the nozzle).

What happens to air as it goes through a jet

engine?

Here's a small volume of air, happily minding its own business at six and

a half miles above the ground. It's about to be sucked into a commercial

jet engine cruising at over five hundred miles per hour, where it will be

squeezed and heated to provide thrust for a jet airliner. Let's follow

this bit of air as it travels through the engine.

The Inlet

Far ahead of the airplane, the speed of the air relative to the engine is

equal to the airplane's flight speed. Our air volume enters the inlet and

slows down considerably. A well-designed inlet will straighten out the

flow, leaving it uniform and without much turbulence. This is important

because compressors and fans need to be fed distortion-free air.

Supersonic inlets, found on many military jets, are usually much more

complex and use shock waves to slow down the air.

The Compressor

The air is squeezed through many blades, all spinning quickly at several

thousand times per minute. The air is forced through several rows of both

spinning and stationary blades. As the air passes each row, the available

space is greatly reduced, and so the air that exits this phase is thirty

or forty times higher in pressure than it was outside the engine. The air

in this state is said to be compressed. The temperature goes up

too; usually over a thousand degrees.

The Combustor

The air is heated in the combustor by burning it with jet fuel. The jet

fuel is squirted into the combustor, where it vaporizes, mixes with the

air, and catches on fire. The temperature of the air leaving the combustor

can be as high as three thousand degrees.

The Turbine

Were you wondering where the power came from when the air went through the

compressor? The power needed to drive all of the compression components

comes from turbines. These kinds of spinning blades, rather than

increasing the energy of the air like a compressor does, instead takes

energy out of the air. This energy is transferred to the compressors by

connecting shafts. The air leaving the turbines is said to be expanded,

which means it's a little lower in pressure and temperature than it was in

the combustor.

The Nozzle

Even though some energy was taken out of the air by the turbines, there

was still enough energy added by the burning fuel to make useful thrust. A

nozzle expands the air even further, by trading the air's energy for

speed. The air gives up its heat and pressure as it goes through the

nozzle's relatively small opening. Like the air leaving a balloon, the

speed and flow rate of the air leaving the nozzle provides the airplane

with thrust.

Jet Engines (Advanced ...)

A jet engine operates on the application of Sir Isaac Newton's third law of physics: for every action there is an equal and opposite reaction. This law is demonstrated in simple terms by releasing an inflated balloon and watching the escaping air propel the balloon in the opposite direction. In the basic turbojet engine, air enters the front intake and is compressed, then forced into combustion chambers where fuel is sprayed into it and the mixture is ignited. Gases which form expand rapidly and are exhausted through the rear of the combustion chambers. These gases exert equal force in all directions, providing forward thrust as they escape to the rear. As the gases leave the engine, they pass through a fan-like set of blades (turbine) which rotates the turbine shaft. This shaft, in turn, rotates the compressor, thereby bringing in a fresh supply of air through the intake. Engine thrust may be increased by the addition of an afterburner section in which extra fuel is sprayed into the exhausting gases which burn to give the added thrust. At approximately 400 mph, one pound of thrust equals one horsepower, but at higher speeds this ratio increases and a pound of thrust is greater than one horsepower. At speeds of less than 400 mph, this ratio decreases.In a turboprop engine, the exhaust gases are also used to rotate a propeller attached to the turbine shaft for increased fuel economy at lower altitudes. A turbofan engine incorporates a fan to produce additional thrust, supplementing that created by the basic turbojet engine, for greater efficiency at high altitudes. The advantages of jet engines over piston engines include lighter weight with greater power, simpler construction and maintenance with fewer moving parts, and efficient operation with cheaper fuel.

Details.....

Jet Propulsion, thrust imparting forward motion to an object, as a reaction to the rearward expulsion of a high-velocity liquid or gaseous stream.

A simple example of jet propulsion is the

motion of an inflated balloon when the air is suddenly discharged. While the

opening is held closed, the air pressure within the balloon is equal in all

directions; when the stem is released, the internal pressure is less at the open

end than at the opposite end, causing the balloon to dart forward. Not the

pressure of the escaping air pushing against the outside atmosphere but the

difference between high and low pressures inside the balloon propels it.

An actual jet engine does not operate quite as simply as a balloon, although the basic principle is the same. More important than pressure imbalance is the acceleration to high velocities of the jet leaving the engine. This is achieved by forces in the engine that enable the gas to flow backward forming the jet. Newton's second law (see Mechanics) shows that these forces are proportional to the rate at which the momentum of the gas is increased. For a jet engine, this is related to the rate of mass flow multiplied by the rearward-leaving jet velocity. Newton's third law, which states that every force must have an equal and opposite reaction, shows that the rearward force is balanced by a forward reaction, known as thrust. This thrusting action is similar to the recoil of a gun, which increases as both the mass of the projectile and its muzzle velocity are increased. High-thrust engines, therefore, require both large rates of mass flow and high jet-exit velocities, which can only be achieved by increasing internal engine pressures and by increasing the volume of the gas by means of combustion.

Jet-propulsion devices are used primarily in high-speed, high-altitude aircraft, in missiles, and in spacecraft (see Airplane; Guided Missiles; Space Exploration). The source of power is a high-energy fuel that is burned at intense pressures to produce the large gas volume needed for high jet-exit velocities. The oxidizer required for the combustion may be the oxygen in the air that is drawn into the engine and compressed, or the oxidizer may be carried in the vehicle, so that the engine is independent of a surrounding atmosphere. Engines that depend on the atmosphere for oxygen include turbojets, turbofans, turboprops, ramjets, and pulse jets (see below). Nonatmospheric engines are usually called rocket engines (see Rocket).

ATMOSPHERIC

JET ENGINES

All atmospheric engines depend on the flow of

a large mass of air that is first compressed, then used to oxidize fuel, and

finally expanded to low pressures through a nozzle in order to achieve a high

jet-exit velocity.

Turbojet

Engines

The most widely used atmospheric engines are

turbojets. After air has been drawn into the engine through an inlet, the air

pressure is increased by a compressor before it enters the combustion chamber (see

Air Compressor). The power required to drive the compressor is provided by a

turbine that is placed between the combustion chamber and the nozzle.

Practically all airborne jet engines use an

axial-flow compressor, in which the air flows generally in the direction of the

shaft axis through alternate rows of stationary and rotating blades, called

stators and rotors. The blades are arranged so that the air enters each row at a

high velocity. As it flows through the blade passage the air is decelerated to a

lower velocity, thereby increasing the pressure. Modern axial-flow compressors

can increase the pressure 24 times in 15 stages, with each set of stators and

rotors making up a stage.

The compressed air then enters the combustion chamber where it is mixed with fuel vapor and then burned. For best performance, the combustion temperature should be the maximum obtainable from the complete combustion of the oxygen and the fuel. This temperature, however, would make the turbine too hot; turbine inlet temperatures, which currently limit turbojet performance, cannot exceed about 1100° C (about 2000° F) because of the thermal limitations of the materials. To reduce the temperature of the turbine inlet, only part of the compressed air is burned. This is achieved by dividing the air as it enters the combustion chamber. Part of the air is mixed with the fuel and ignited; the remainder is used to cool the turbine.

In the turbine, which acts in opposite fashion to the compressor, the gases are partially expanded through alternate stator and rotor passages. At the entry to each blade row, the velocity is low, allowing the gas to expand and speed up in the passage while it turns the rotor. The turbine provides the power to drive the compressor, to which it is connected by a shaft through the center of the engine, and it also provides the power for the fuel pump, generator, and other accessories.

The gases, which are now at an intermediate pressure, are finally expanded through the rearward-facing nozzle to reach the desired high jet-exit velocity. The greatest thrust would be obtained if the nozzle expanded the gases to the pressure of the surrounding atmosphere. In practice, however, such nozzles would be too large and too heavy. Actual nozzles are made shorter in order to provide higher exit pressures and a somewhat reduced engine performance.

A turbojet engine cannot start directly from rest; the engine must first be induced to spin by an external starting motor. The fuel is then ignited by a heated plug. Once the engine is running, however, combustion is maintained without spark plugs.

The thrust delivered by a turbojet decreases as the surrounding air temperature increases because the decreased density of the hot air reduces the mass flow through the engine. On hot days, takeoff thrust can be increased by injecting water at the compressor inlet and allowing the evaporating water to cool the air.

In military engines, bursts of speed or additional thrust for takeoff and climb can be provided by a second burner, or afterburner, installed between the turbine and the nozzle. In the afterburner, more fuel is added to burn the oxygen in the air that is not used in the combustion chamber; this process increases both the air volume and the jet velocity. The low efficiency of an afterburner, however, restricts its use to situations requiring a great burst of speed.

Turbofans

or Bypass Engines

The turbofan engine is an improvement on the

basic turbojet. Part of the incoming air is only partially compressed and then

bypassed in an outer shell beyond the turbine. This air is then mixed with the

hot turbine-exhaust gases before they reach the nozzle. A bypass engine has

greater thrust for takeoff and climb, and increased efficiency; the bypass cools

the engine and reduces noise level.

In some fan engines the bypass air is not

remixed in the engine but exhausted directly. In this type of bypass engine,

only about one-sixth of the incoming air goes through the whole engine; the

remaining five-sixths is compressed only in the first compressor or fan stage

and then exhausted. Different rotational speeds are required for the high- and

low-pressure portions of the engine. This difference is achieved by having two

separate turbine-compressor combinations running on two concentric shafts or

twin spools. Two high-pressure turbine stages drive the 11 high-pressure

compressor stages mounted on the outer shaft, and 4 turbine stages provide power

for the fan and 4 low-pressure compressor stages on the inner shaft. An example

of an engine of this type is the JT9D-3 jet engine, which weighs about 3850 kg

(about 8470 lb) and can develop a takeoff thrust of about 20,000 kg (about

44,000 lb). This is more than double the thrust available for the largest

commercial planes before the Boeing 747.

Current research in turbojet and turbofan engines is largely directed to achieving more efficient operation of the compressors and turbines, to devising special turbine-blade cooling systems to permit higher turbine-inlet temperatures, and to reducing jet noise.

Turboprop

Engines

In a turboprop engine a propeller mounted in

front of the jet engine is driven either by a second, or free, turbine or by

additional stages from the turbine that supplies power to the compressor. About

90 percent of the energy of the expanding gases is absorbed in the turbine

portion that drives the propeller, leaving only about 10 percent to accelerate

the exhaust jet. The exhaust jet, therefore, contributes only a small fraction

to the overall propulsive thrust. Turboprops have certain advantages for small

and medium-sized planes at speeds of up to about 480 to 640 km/h (about 300 to

400 mph). They cannot compete, however, with turbojets or fanjets for very large

planes and for higher speeds.

Ramjets

The air rushing toward the inlet of an engine

flying at high speeds is partially compressed by the so-called ram effect. If

the air speed is high enough, this compression can be sufficient to operate an

engine without either compressor or turbine. The ramjet has been called a flying

stovepipe, because it is open at both ends and has only fuel nozzles in the

middle. A straight stovepipe would not work, however; a ramjet must have a

properly shaped inlet-diffusion section to produce low-velocity, high-pressure

air at the combustion section, and it must also have a properly shaped exhaust

nozzle. Ramjets can operate at speeds above 320 km/h (about 200 mph), although

they become practical for military applications only at very high or supersonic

speeds. Because the ramjet depends on the compression of the inrushing air for

its operation, a vehicle powered by a ramjet must first be accelerated by other

means to a sufficiently high speed.

Pulse Jets A pulse jet is similar to a ramjet, except that a series of spring-loaded shutter-type valves is located ahead of the combustion section. In a pulse jet, combustion is intermittent or pulsing rather than continuous. Air is admitted through the valves, and combustion is initiated, which increases the pressure, closing the valves to prevent backflow through the inlet. The hot gases are expelled through the rear nozzle, producing thrust and lowering the pressure to the point that the valves may open and admit fresh air. Then the cycle is repeated. The most widely known pulse jet was the German V-1 missile, or buzz bomb, used near the end of World War II, which fired at a rate of about 40 cycles per sec.

The pulsing effect can also be achieved in a valveless engine, or wave engine, in which the cycling depends on pressure waves traveling back and forth through a properly scaled engine. A pulse-jet engine delivers thrust at zero speed and can be started from rest, but the maximum possible flight speeds are below 960 km/h (600 mph). Poor efficiency, severe vibration, and high noise limit its use to low-cost, pilotless vehicles.

Hydraulic Jet Propulsion Jet-propulsion devices are not limited to using gases as the working fluid; liquids, such as water, may also be used. A simple example of a liquid jet device that operates on the reaction principle is the spinning lawn sprinkler.

Attempts to develop hydraulic jet propulsion for ships were made by British and Swedish engineers as early as the 1920s. In such a system, water is inducted at the forward end of the ship, passed through high-pressure pumps, and then exhausted at the stern through one or more nozzles that produce high-speed water jets. Both highly efficient pumps and high speeds are required to make hydraulic jets competitive with other means of ship propulsion. Although water-jet propulsion has not proved successful for large vessels, it is currently employed in some high-speed boats and pleasure craft.

HISTORY Jet power as a form of propulsion has been known for hundreds of years, although its use for propelling vehicles that carry loads is comparatively recent. The earliest known reaction engine was an experimental, steam-operated device developed about the 3rd century BC by the Greek mathematician and scientist Hero of Alexandria. Known as the aeolipile, Hero's device did no practical work, although it demonstrated that a jet of steam escaping to the rear drives its generator forward. The aeolipile consisted of a spherical chamber into which steam was fed through hollow supports. The steam was allowed to escape from two bent tubes on opposite sides of the sphere, and the reaction to the force of the escaping steam caused the sphere to rotate.

The development (1629) of the steam turbine is credited to the Italian engineer Giovanni Branca, who directed a steam jet against a turbine wheel, which in turn powered a stamp mill. The first recorded patent for a gas turbine was obtained in 1791 by the British inventor John Barber.

In 1910, seven years after the first flights by the American inventors Orville and Wilbur Wright, the French scientist Henri Marie Coanda designed and built a jet-propelled biplane, which took off and flew under its own power with Coanda as pilot. Coanda used an engine that he termed a reaction motor, but, discouraged by the lack of public acceptance of his aircraft, he abandoned his experiments.

During the next 20 years the gas turbine was developed further in both the United States and Europe. One result of the experimental work of that period was the perfection in 1918 of a turbosupercharger driver by an exhaust gas turbine for conventional aircraft engines. In the early 1930s many patents covering gas turbines were awarded to a number of European engineers. The patent granted the British aeronautical engineer Sir Frank Whittle in 1930 is generally conceded to have outlined the first practical form of the modern gas turbine. In 1935 Whittle applied his basic design to the development of the W-1 turbojet engine, which made its first flight in 1941.

Meanwhile, the French aeronautical engineer René Leduc had exhibited (1938) a model of the ramjet in Paris, and a jet airplane that was powered by an axial-flow turbojet designed by the German engineer Hans Joachim Pabst von Ohain made its first flight in 1939. In the following year, under the direction of the aeronautical engineer Secundo Campini, the Italians developed an airplane powered by a turboprop engine with a reciprocating-engine-driven compressor. The first American-built jet airplane, the Bell XP-59, was powered by the General Electric 1-16 turbojet, adapted from Whittle's design in 1942. The first jet engine of exclusively American design was produced by Westinghouse Electric Corp. for the U.S. Navy in 1944.

From a principle first described in 1906, the pulse jet was developed by the German engineer Paul Schmidt, who received his first patent in 1931. The V-1, or buzz bomb, first flown in 1942, was powered by pulse jet. Also in the mid-1940s the first commercial airline flights using turboprop engines occurred. In 1947 the Bell X-1 experimental airplane, powered by a four-chambered liquid-rocket engine and carried to the stratosphere in the belly of a bomber for launching, was the first pilot-operated craft to break the sound barrier. Subsequently the Douglas Skyrocket experimental airplane, powered by a jet engine in addition to a liquid-rocket engine, broke the sound barrier at low altitude after taking off under its own power.

The first commercial jet airplane, the British Comet, was flown in 1952, but this service was stopped after two serious accidents in 1954. In the U.S., the Boeing 707 jet was the first jet airplane to be tested commercially, in 1954. Commercial flights began in 1958.

The continuous development of jet propulsion for air power has resulted in such advances as piloted aircraft capable of attaining speeds several times greater than the speed of sound, and intercontinental ballistic missiles and artificial satellites launched by powerful rockets.